Life-Cycle Assesment (LCA) BYBORRE

This document* offers insight into the dynamic LCA’s data sources and calculations of BYBORRE’s textile packages and its associated environmental impact.

SUMMARY

The scope of this first LCA is cradle-to-gate, assessing the GHG emissions (CO2eq), water usage (L) and energy usage (kWh) from raw material extraction to the production of the finished textile product; as well as the material wastage (if any) across various stages.

BYBORRE collaborates with various stakeholders up- and downstream (of) the textile supply chain to make responsible and fit to purpose textiles. For this assessment, we have consolidated primary data from our major yarn suppliers in Germany, Italy, Poland, and our textile production partners in Belgium and Italy.

The consolidated data from our stakeholders is the primary source and the secondary source is Ecochain (Ecoinvent) and the Higg Materials Sustainability Index (MSI).

All data sources are listed under Limitations and Data Sources.

* This is a living document that will be updated based on the growing availability of relevant data.

1. INTRODUCTION

1.1 Mission

The ultimate goal of BYBORRE is to enable and educate an entire generation of creators about designing more fit for purpose and responsible textiles while reinventing the textile industry along the way.

In the textile design phase, 80% of the environmental footprint (e.g. material and process waste and emissions) of a textile (the output) is set in stone. Every decision matters.

The entire textile supply chain is affected by aforementioned design decisions. In our pursuit of understanding the impact of our textile design and production, we set up a Life-Cycle Assessment (LCA) to intimately get to know our supply chain. The textile packages, as used in the LCA, represent our offerings to date in our online textile design tool, Create™. This way, we can give creators direct feedback about the decisions they make in the textile design phase.

1.2 Life-Cycle Assessment (LCA) Framework

A Life Cycle Assessment (LCA) is a methodology to assess environmental impacts associated with all the stages of the life-cycle of a product, process, or service. It is a framework standardised by International Organisation for Standardisation (ISO) which unifies the way impact is measured and, more importantly, compared all over the world. The type of LCA we use at BYBORRE is dynamic, meaning it is based on a supply chain modelling perspective instead of an accounting one. Practically, this means that our LCA lives in software that can be easily updated, enabling us to pull out new results the moment new and relevant data becomes available. More importantly, that way we can keep our design decision feedback in Create™ on par.

Figure 1. shows the design of our LCA, including the definition of its variables and assessment. With us, no two textiles are alike, so we could not make do with one supply chain for one product. Instead, we had to adopt a building block approach allowing us to configure many combinations of yarn, production, finishing and transport type.

1.3 Goal and Scope

The goal of LCA is to measure and assess the environmental impact of manufacturing textiles with BYBORRE. For this first LCA, cradle-to-gate is defined to include raw material inputs into yarn production, yarn dyeing, textile manufacturing (circular knitting), finishing, packaging, and transportation.

We teamed up with Amsterdam-based LCA research firm Ecochain to get our first impact results. Ecochain’s LCA software, Mobius (1), uses the methodology of Object-Based Footprinting to conduct an LCA on a consolidated data set, resulting in a footprint at a product level. The LCA uses primary data whenever available; otherwise it references secondary data and existing LCAs for select processes.

We worked closely with our yarn suppliers and production partners, and asked them to share with us in-depth information about every aspect and input that goes into making our textiles. We then plugged the supplier’s data into Mobius, and complemented our dataset with secondary data from Ecoinvent in order to obtain an impact overview of each textile package.

1.4 Functional Unit

The functional unit for this LCA is 1 kg of textile per BYBORRE textile package. The outcome of the LCA is expressed as water usage (L), energy usage (kWh) and GHG emissions (CO2eq).

2. BYBORRE PRODUCT OVERVIEW

2.1 BYBORRE Textile Package

BYBORRE has hand-picked the most responsible synthetic and natural yarns and developed curated textile packages for creators to choose from. This way, we inspire creators to design with responsible materials, whilst enjoying creative freedom.

Figure 2. outlines the major steps involved in making a BYBORRE textile. We gathered primary data from our suppliers and production partners for realistic consumption data to inform the assessment. All of the yarns used in BYBORRE textiles are produced with recycled/organic raw material, offering a lower environmental impact. As dyeing textiles is highly water and chemical-intensive, we choose to only use dyed yarns, and not dye our textiles. This eliminates additional transport (back-and-forth) between production facilities and dyeing facilities.

2.2 Conventional Textile Package

Our conventional yarn comparisons are in line with Textile Exchange’s conventional assumptions in their Corporate Fiber & Materials Benchmark (2), Program Sustainability Weight. As BYBORRE textiles are different from conventional knitted textiles, we recreated comparable textile packages on Mobius with conventional yarns and industry standard processes for comparison to BYBORRE textile packages.

Figure 3. outlines the major steps involved in making a conventional textile. To determine the environmental impact of conventional yarns and production processes, we used secondary data from the Ecoinvent (v3.6) and the Higg Materials Sustainability Index (MSI).The environmental impact of conventional textiles is higher as the virgin raw material production consumes great amounts of energy, water and chemicals. On top, it includes additional transport movements due to the extra steps involved at the dyeing and finishing stages.

2.3 BYBORRE Textiles vs Conventional Textiles

To calculate the difference in environmental impact in comparison to conventional textiles, we also decided to express the output of the LCA as comparison percentage (%). We needed to compare the BYBORRE textiles packages (BTP) to a conventional textile package (CTP). With this comparison, creators can better understand the environmental impact of the textiles they design and make more conscious decisions when it comes to submitting their textiles for production.

Methodology behind savings calculation:

GHG Emissions % (KG CO2eq): These refer to the GHG emissions (CO2eq) saved with producing textiles with BYBORRE compared to a conventional system.

1- {BTP emissions (KG CO2eq ) per KG textile - CTP emissions (KG CO2eq ) per KG textile }= GHG Emissions %

Water usage % (L): These refer to the water saved with producing textiles with BYBORRE compared to a conventional system.

1- {BTP water usage (liters)per KG textile - CTP water usage (KG CO2eq ) per KG textile} = Water usage %

Energy usage % (kWh): These refer to the energy saved with producing textiles with BYBORRE compared to a conventional system.

1- {BTP energy usage (kWh) per KG textile - CTP energy usage (kWh) per KG textile} = Energy usage %

These outputs also help us build a heat map for improvements and future Create™ textile packages to increase the savings every year and onboard the latest material and textile production innovations to reduce our environmental impact, and that of our clients, where we can.

3. LIMITATIONS AND DATA SOURCES

3.1 LIMITATIONS

Any environmental assessment that does not include the impact per wear or use, is by default leaving out a significant chunk of a textile product’s environmental impact. As our core process currently stops at the production of textiles, and does not include (control over) its end-product, this LCA is cradle-to-gate, and not cradle-to-grave. We do feel called to find ways to emphasise the opportunity of reducing the environmental impact per wear and use in future updates of Create™.

This LCA covers tier 1, 2 and 3 of our suppliers. BYBORRE’s 1st tier (production and processing), 2nd tier (yarn + material suppliers), 3rd tier (raw material + machine suppliers) supply chain. Our yarn suppliers include Sinterama SPA, Zwickauer Kammgarn GmbH (ZKS), Filmar S.p.A, Parley and Südwolle Group GmbH & Co. KG. Nesatex s.r.l and LAVA TEXTILES are our textile production partner included in this assessment. The LCA contains supplier-specific data from the year 2021/2022. Thanks to the support and transparency of our supply chain

partners, we are able to model exact LCA results for the majority of our processes.

All raw materials except recycled nylon have been captured by the LCA analysis processed in full detail with Echochain. Individual details of ZKS premium yarn were not available, only final impact variables in kg CO2eq were shared. The LCA results are based on the best of industry knowledge and resources in 2022/2023. We will update these results annually based on the growing availability of relevant data.

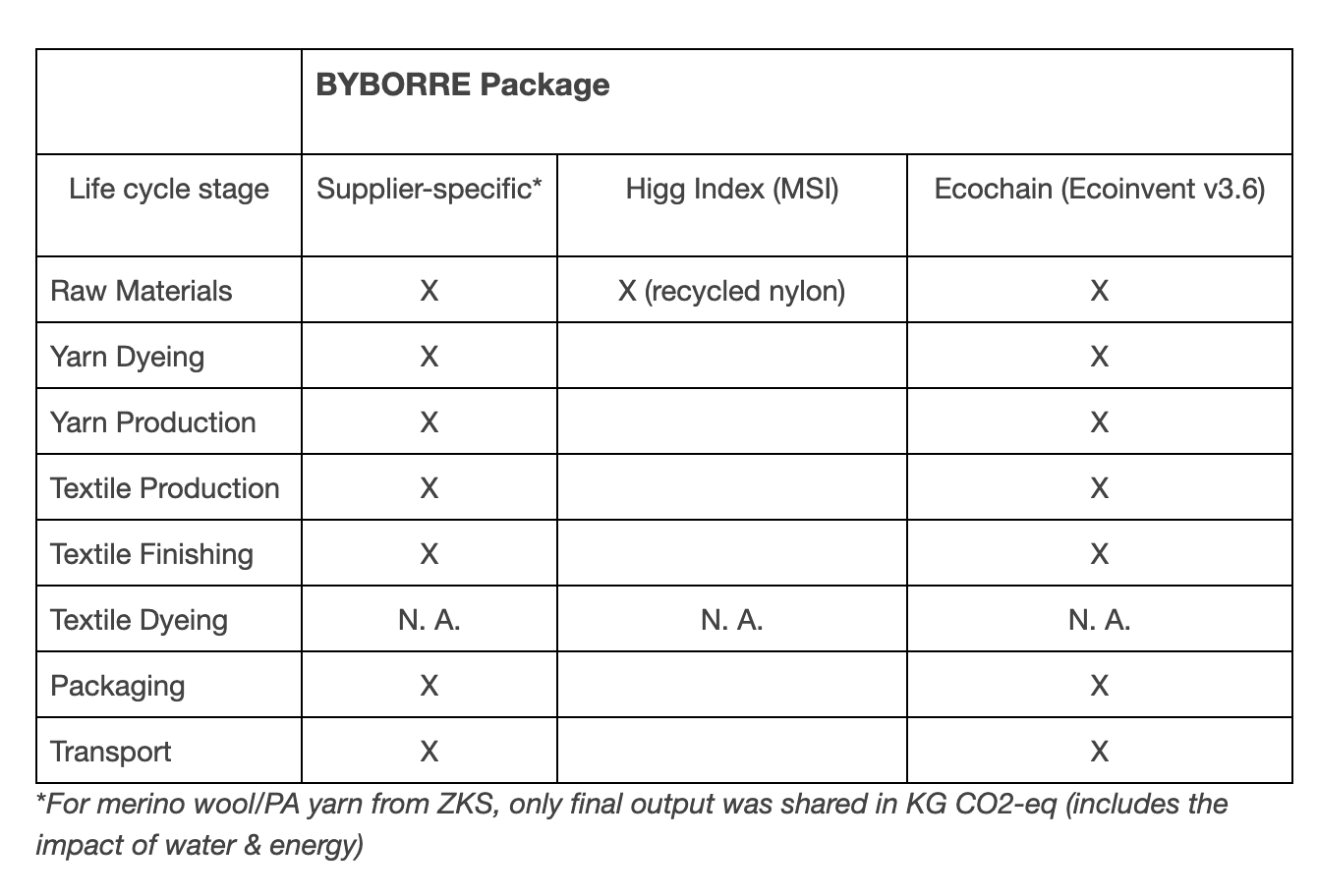

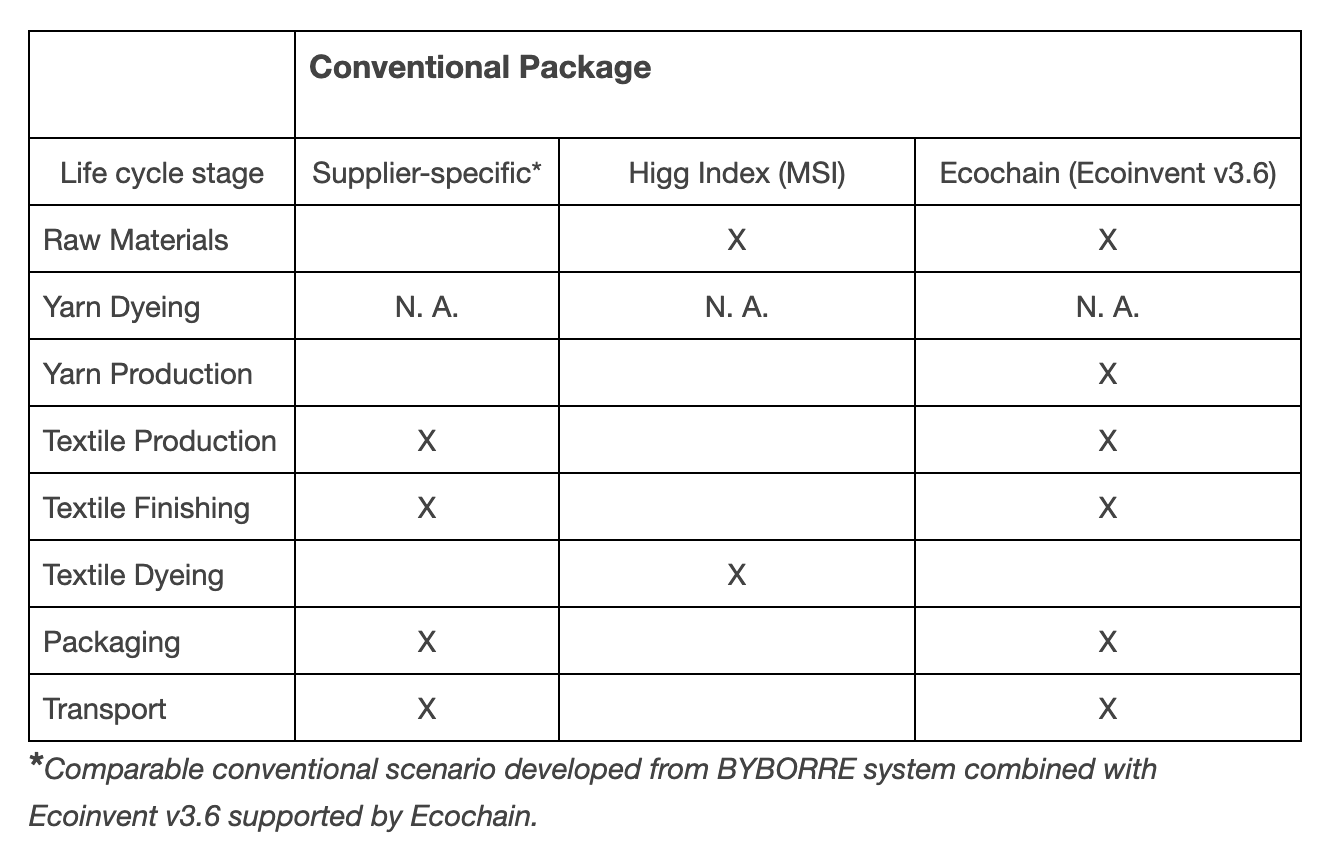

3.1 DATA SOURCES

Sources used to calculate the environmental footprint include a mix of primary (majorly) and secondary data, including other LCAs, and materials databases. A summary of key data sources by life cycle stage is listed below:

4. GLOSSARY AND REFERENCES

4.1 Glossary

Cradle-to-gate

The system boundaries for the LCA, e.g. from cradle (“raw material extraction”) to gate (“point of distribution”).

Create™

BYBORRE Create™ is a design platform that enables creators to design textiles that are more fit to purpose and responsible for the products we use every day.

Creator

Creators are those working with textiles and/or using textiles in the products they make.

CO2-eq

Carbon dioxide equivalent (CO2eq) stands for a unit based on the global warming potential (GWP) of different greenhouse gases. The CO2eq unit measures the environmental impact of one tonne of these greenhouse gases in comparison to the impact of one tonne of CO2.

Fit to purpose textile

A textile that is designed with the end in mind, focused on functionality and durability.

Greenhouse Gas (GHG)

Greenhouse gases, or GHGs, are compound gases that trap heat or longwave radiation in the atmosphere.

Impact

The sustained changes experienced by our stakeholders in an area over time as a result of our actions.

Knit structure

A type of knitting technique, adopted or invented by BYBORRE.

Production Partner

A partner for manufacturing our bulk order textiles.

Responsible/Preferred materials

Materials that have improved social and environmental impacts (definition by Textile Exchange).

Textile Packages

A textile package is a combination of knit structure, yarn composition, suited for given use cases.

Yarn Supplier

A supplier of yarns, the primary material input for textiles.

4.2 References